The researchers claim that, unlike traditional magnetorheological materials, their textiles do not rely on heavy magnetic powders and potentially dangerous, strong magnetic fields in order to function. The Director of the PolyU Research Institute for Intelligent Wearable Systems, Professor Tao Xiaoming, explains: “The core objective of our research team is to overcome the application limits of traditional magnetorheological technology, extending it to fibre form, and enabling precise intelligent modulation, while remaining compatible with textile properties such as softness and breathability.”

To make their textiles, the researchers first melt-spin fibres from a low-density polyethene (LDPE) filled with carbonyl iron particles (CIPs). The fibres are then subjected to high-speed drawing in order to increase their Young's modulus and breaking strength, and to distribute the CIPs along their length. The resulting fibres have a diameter of 57 µm and can be produced at speeds of approximately 2 km.h−1. Seven such fibres are twisted and heat-set to create a yarn, which can then be used to produce woven and cut-pile fabrics.

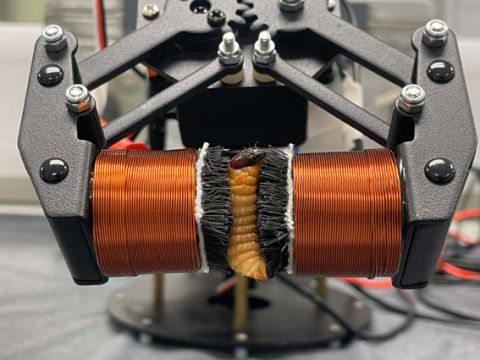

The researchers have used the yarns to create three fabrics. First, they have created a cut-pile fabric that can be applied to the pincer-tips of a robotic gripper, enabling it to grasp soft, fragile and/or irregularly shaped items – such as insect larva, tofu, blueberries mung bean cake, potato chips and fusilli – much like human fingers, significantly reducing the risk of damaging or deforming the items compared with other gripping methods. The stiffness of the piles is controlled using a magnetic field, enabling the deformation of the pincer-tips to be customised to the item being grasped.

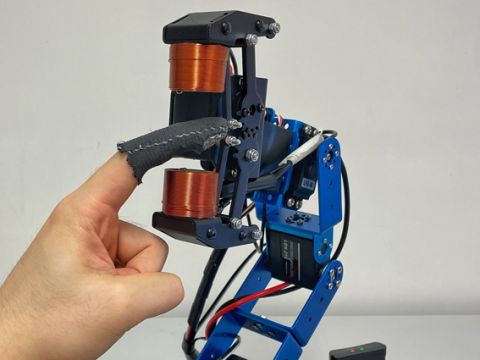

Second, the researchers have created a fabric-based haptic finger-sleeve. When a person inserts a finger into it, the sleeve can accurately replicate the surface textures and tactile hardness of different objects. Lightweight and comfortable to wear, the sleeve could be used for remote surgical training, stroke rehabilitation training and virtual fitting, and is slimmer and lighter in weight than currently available haptic gloves.

Finally, the researchers have created fabrics with permeabilities that can be altered by magnetic fields, enabling the fabrics to become either more or less porous to air and water vapour, thereby enhancing the comfort of their wearer.

Tao says: “The key breakthrough of this research lies in converting traditional rigid magnetic devices into flexible alternatives. This success can be extended to the development of hard magnetic fibre materials, laying a foundation for the next generation of soft robotics, electromagnetic devices and wearable technologies.”

An Assistant Professor at PolyU's School of Fashion and Textiles, Pu Junhong, concludes: “From raw-material selection to processing technology, we have taken industrialisation needs into consideration. We adopt commodity-grade, mass production-ready raw materials and mature processing techniques, paving the way for rapid translation in fields such as food production, medical rehabilitation and metaverse interaction.”