The lead researcher on the project, Professor Guan Yeoh, says: “We chose cotton because it is one of the most common materials used in the clothing and textile industry. What we have achieved is a solution that does not smell and does not change the softness of the cotton once it is sprayed-on, so the item of clothing still feels the same as before.”

The spray-on coating comprises phosphorous and nitrogen elements, which act as a binder, and a water-soluble cellulose extract that is rich in carbon. The coating dries instantaneously and binds to natural fibres. When exposed to flame, the phosphorus in the coating tightens the carbon layer that forms, creating a barrier to heat.

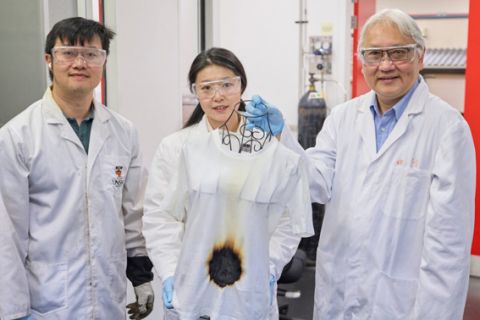

In laboratory tests, two pieces of cotton, one sprayed with the coating and the other untreated, were exposed to a direct flame. The researchers found that the coated fabric took twice as long to ignite and released half the heat than the untreated fabric. The flame also only charred the treated fabric, whereas the untreated fabric burned in seconds. The test also showed a reduction in peak heat-release rate (PHRR) of about 89%, meaning the treated cotton material produces only 11% of the maximum heat output of the untreated sample. Lowering the PHRR is critical to slowing-down the rate fire grows, reducing heat intensity, and thereby the chance of a material igniting almost instantly.

Yeoh says: “Our results also show that when exposed to heat, the surface temperatures on the [treated] textiles could be reduced to 30% to 40% of the heat temperature. In simulated fire environments, treated fabrics kept temperatures on the skin-side below 40°C, even when the external environment hit 100°C.”

The coating is strong enough to withstand light contact with water, but will dissolve during laundering. To test this, the team washed the treated fabric and exposed it to a flame. It burned just as quickly as an untreated fabric. Yeoh says: “What we wanted to demonstrate was whether washing-off the coating would return the fabric to its original flammability, and it did, which shows that the coating provides that protective layer on your shirt or pants until you wash it off.”

Yeoh expects to see the coating available commercially within the next year. He says: "There are still a few hurdles to clear, but the biggest one, fire-performance, is already behind us. The formulation consists of non-toxic compounds with a neutral pH of 7 and, in our tests, we did not observe any skin irritations when sprayed in low doses. However, we still need to do further dermatological testing to fully understand its effects on the skin.”

Yeoh and his team are also testing the performance of the coating on other materials, such as polyester (PES).