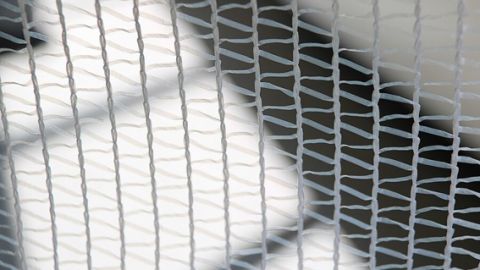

The company, of Obertshausen, Germany, says that the fine nets, which can be knitted from polyethylene (PE) tapes on its RS 2 EL Raschel machines, are strong and durable.

Planted in the ground in late autumn, tulip bulbs produce flowers the following spring, which are cut shortly after blooming. The plants then focus all of their energies on forming daughter bulbs. In mid-July, the bulbs are harvested – up to 100 per square metre – and nets are used to do this efficiently.

The grid-like nets are buried in the ground above and below the bulbs across the entire field. For harvesting, the two layers are pulled from the ground together by machine and rolled-up separately. When the nets are separated, the bulbs roll into the machine’s harvesting basket.

If the nets become too damaged for use in agriculture – for example, after being broken by rodents – they are still in demand on the front lines of the conflict in Ukraine, where they help protect Ukrainian soldiers and civilians against drone attacks. The nets are strung-up over roads, buildings and military positions, where they snag kamikaze drones – drones loaded with explosives that target personnel and vehicles – preventing them from reaching their targets.

Karl Mayer says that its RS 2 EL Raschel warp-knitting machine produces high-quality tulip nets efficiently. The robust, open-structured fabrics are knitted at a gauge of E 6, with a threading of 1 in – 2 out, and a stitch density of 1.5 to 1.8 stitches per centimetre. The working width of the machine is 5.7 m (226 inches). PE film is cut into tapes by an integrated unit, stretched, then fed directly into the warp-knitting unit. It is then processed as a pillar stitch (with a tape width of approximately 1.7-2 mm and a tape thickness of 25-30 µm) and as a weft-inlay (with a tape width of approximately 1.0-1.5 mm and a tape thickness of 25-30 µm). Three panels are produced per machine, each wound onto rolls up to 800 mm in diameter.

In addition to tulip nets, round-bale and pallet nets can also be produced on the RS 2 EL Raschel machine.