More than half of the 7.5 million bales of cotton produced in the USA each year are consumed in the manufacture of fabrics for clothing. Formaldehyde-based resins have traditionally been used as a finishing agent for these fabrics; the resins bind to cellulose fibres, forming chemical bridges that help to prevent them from wrinkling or stretching. While formaldehyde is cheap, easy to use and highly reactive, at high concentrations it is considered a carcinogen, and can also irritate the skin and respiratory systems of humans. PFAS-containing coatings are used to render cotton fabrics hydrophobic, but exposure to PFAS has been linked to decreased fertility, developmental delays in children, increased risk of some cancers, disruption to the immune system, interference with hormones and increased cholesterol, and their use is subject to increasingly stringent regulation.

To eliminate the need for formaldehyde-based resins and PFAS in cotton-fabric finishing, a group led by a Professor of Pulp and Paper Science and Technology at North Carolina State University (NCSU) in Raleigh, Richard Venditti(1), set-out to create an alternative by chemically altering oil from cotton seeds. In work funded by Cotton Inc, of Cary, North Carolina, USA, the group inserted epoxy groups along the long carbon chains that make-up the oil molecules, enabling them to create strong chemical bonds with cellulose fibres and with eachother, thereby forming a polymer and making the fabric hydrophobic. The epoxy groups also create oil-molecule bridges between cellulose fibres, making cotton fabrics resistant to wrinkling.

As it can be harvested at the same time as cotton fibres, the cotton seed for epoxidised cottonseed oil (ECSO) is as inexpensive, easy to use and effective as formaldehyde resins.

A graduate student at NCSU, Taylor Kanipe, says: "Epoxidised vegetable oils have a range of applications. While native cottonseed oil lacks the reactivity of formaldehyde-based resins, this simple epoxidation process produces a safer, more user-friendly alternative for applications like durable press finishes.”

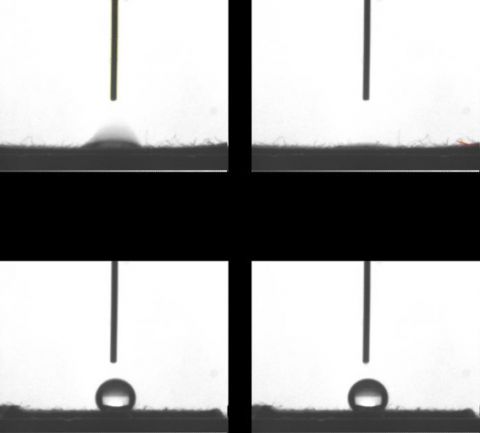

The researchers weighed and chemically analysed the ECSO-treated fabric using infrared spectroscopy to ensure the ECSO molecules had successfully bonded to the fabric’s surface. To evaluate the finished fabric’s water-repellent qualities, the researchers used a high-speed camera to measure the contact angle at which water droplets would interact with its surface. The larger the angle between the water droplet and the surface of the fabric, the greater the water-resistance. Untreated fabric showed no contact angle (in other words, the water was fully absorbed into the fabric), while ECSO-treated fabric showed a contact angle of 125°, indicating a significant increase in its water-repellence.

In future studies, the researchers will test the tear-strength, durability and wrinkle-resistance of ECSO-treated cotton. The team’s ultimate goal is to create a process for treating cotton with an ECSO- and water-based emulsion.

Venditti concludes: “If we can achieve our goal of changing the properties of the cotton fabric — making it anti-wrinkle, anti-staining and water-resistant — using a water-based process, we will have a green process for putting a bio-based material onto cotton as a replacement for formaldehyde- and PFAS-based finishes.”