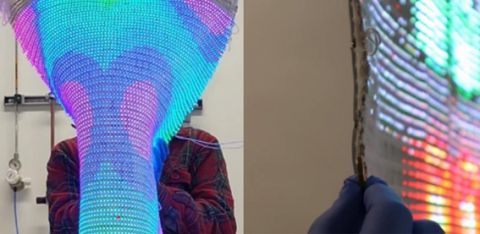

Significantly, the researchers claim that the 1.2-m (46-inch) light-emitting diode (LED) display can be produced on standard weaving equipment and can be folded, rolled and bent without affecting its performance. They believe that the display could be used, for instance, to create curtains that also function as televisions, energy-harvesting carpets and interactive, self-powered clothing.

The display comprises 84 × 76 RGB LEDs mounted onto copper fibres and woven with cotton fibres line-by-line, asymmetrically, so as to prevent the distortion of the images it shows.

The fibres used to create the accompanying devices have all been treated so that they can withstand the deformations necessary for them to be processed on standard weaving equipment. They are connected using highly conductive, silver-coated polyamide (PA) fibres that allow them to transfer signals to an assigned controller that, in turn, relays the information to the LED display.

The fibre-based devices are:

- a square spiral, radio-frequency antenna embroidered from silver-coated PA fibres;

- photodetectors comprising a photoactive layer made from aluminium, zinc oxide and graphene on polyethylene naphthalate (PEN) fibres, encapsulated within an epoxy sheath;

- sensors made from silver-coated PA fibres that exhibit a change in their resistance when touched. These are woven into the textile in the weft and warp directions with respective spacings of 2 and 3 cm. The weft fibres are encapsulated by a polyolefin tube, while the warp fibres are left exposed to air;

- temperature sensors comprising two core–shell copper–copper oxide fibres twisted together. Their resistances continuously decrease when exposed to increasing temperatures, from 5°C up to 70°C;

- double-twisted fibre supercapacitors, which consist of a gel-electrolyte placed between carbon-fibre bundles and serve as a trigger switch between the power supply and the textile display;

- a biosensor, comprising a fibre-based transistor and resistor coupled to an electrocardiogram (ECG) pad.

The resulting textile can operate as a display, monitor various inputs or store energy for later use. The fabric can detect radio-frequency signals, touch, light and temperature.

Professor Jong min Kim, from the University of Cambridge’s Department of Engineering, who co-led the research with Luigi Occhipinti and Professor Manish Chhowalla, says: “This is a step towards the full exploitation of sustainable, convenient e-fibres and e-textiles in daily applications, and it is only the beginning.”

Occhipinti adds: “By unleashing the full potential of textile manufacturing, we could soon see smart and energy-autonomous Internet-of-things devices that are seamlessly integrated into everyday objects and many other sector applications.”

The researchers are now working to make the fibre-based devices from sustainable materials.