The researchers have manufactured approximately 450 kg (one thousand pounds) of the fibre from yeast biomass – composed of proteins, lipids (fatty molecules) and sugars – in a factory in Germany and have used this data to conduct a life-cycle analysis. They found that the commercial-scale production of the yeast-based fibre used considerably fewer resources, including far less land, than the production of wool fibre.

Pearce Professor of Engineering and Huck Chair in Biomimetic Materials at Penn State, Melik Demirel, says: “We successfully demonstrated that this material can be made cheaply – for US$6 or less per kilogramme, compared with wool’s US$10–12 per kilogramme – with significantly less water and land, but improved performance compared with any other natural or processed fibres, while also nearly eliminating greenhouse-gas emissions. The saved resources could be applied elsewhere, like repurposing land to grow food crops.”

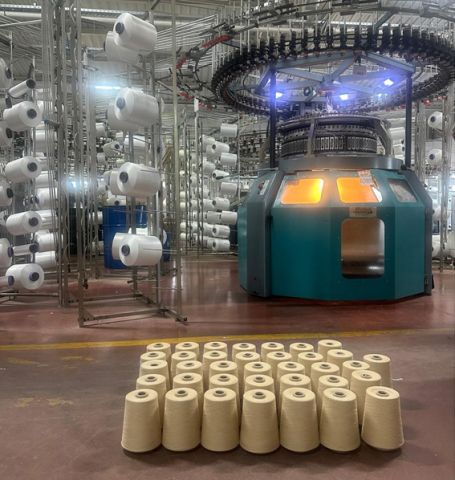

Demirel’s team has spent over a decade developing a process to produce a fibre from proteins. “We can pull the proteins as an aggregate – mimicking naturally occurring protein accumulations called amyloids – from the yeast, dissolve the resulting pulp in a solution, and push that through a device called a spinneret that uses tiny spigots to make continuous fibres”, Demirel says, explaining that the fibres are then washed, dried and spun into yarn that can then be woven into fabric. He also notes that the fibres are biodegradable. He continues: “The key is the solution used to dissolve the pulp. This solvent is the same one used to produce lyocell, the fibre derived from cellulose, or wood pulp. We can recover 99.6% of the solvent used to re-use it in future production cycles.”

Demirel and his team plan to investigate further the viability of yeast-based fibres at a commercial scale. He concludes: “By leveraging biomanufacturing, we can produce sustainable, high-performance fibres that do not compete with food crops for land, water or nutrients. Adopting biomanufacturing-based protein fibres would mark a significant advancement towards a future where fibre needs are fulfilled without compromising the planet's capacity to nourish its growing population. We can make significant strides towards achieving the ‘Zero Hunger’ goal, ensuring everyone can access nutritious food while promoting sustainable development goals.”