The researchers claim that the fibre can used for the production of smart textiles that, unlike conventional smart textiles comprising fabric, metal wires, plastic substrates and adhesives, break-down in landfills.

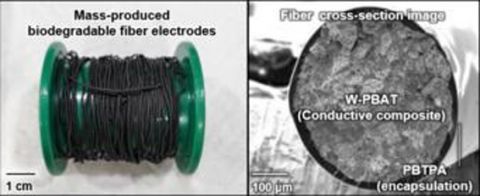

The researchers make the core of the fibre by dry-jet wet-spinning an ink of poly(butylene adipate-co-terephthalate) (PBAT) loaded with electrically conductive tungsten microparticles into a coagulation bath. In a second bath, this core is then coated with a layer of flexible, water-resistant polyanhydride (PBTPA) that enhances the mechanical stability of the resulting fibre without compromising its biodegradability. The fibre demonstrates an electrical conductivity of approximately 2500 S.m–1, can be stretched by up to 38% without breaking, and can endure over 20 cycles of laundering and 5000 bending cycles—performance metrics similar to or better than many existing fibres used for the production of smart textiles, according to the research team.

Using their scalable dry-jet wet-spinning process, the researchers are able to produce fibres of lengths exceeding ten metres in a continuous run.

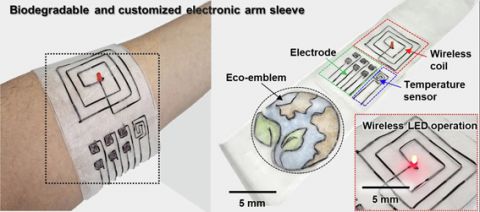

To validate its performance, the researchers integrated the fibre into a wearable smart sleeve featuring a temperature sensor, electromyography (EMG) electrodes and a wireless power coil. The device operated reliably under dynamic movements and environmental stress. After use, the entire system – including an embroidered emblem – began to decompose when exposed to soil or enzymes, fully disintegrating within a few months.

One of the lead researchers on the project, Professor Seung-Kyun Kang, says: “This is more than just a new material—it is a platform for sustainable electronics. We have shown that you can have high-functioning wearable devices that do not become [electronic] waste after their useful life ends.”

Kang's colleague, Jae-Young Bae, adds: "The ability to design electronics that match the lifecycle of the application – and then gracefully disappear – opens-up new possibilities in medical patches, smart uniforms, environmental sensors and beyond. We are especially excited about the potential for use in disposable healthcare systems that do not contribute to long-term pollution.”

The team now plans to create fibre-based memory and logic components, and are exploring triggerable degradation mechanisms, such as light, heat and pH, that would enable the lifespans of the fibres to be programmed.