Certain professionals have chosen an occupation that puts them in danger from aggression and violence every day. They are the men and women who protect us. In response to their needs, slash-resistant clothing has been developed to provide high levels of cut-protection in areas where commonly used body armour and other types of personal protective equipment (PPE) leave their bodies exposed and vulnerable. All such garments are made from high-performance cut-resistant fabrics.

The area at the side of the neck and around the throat contains the carotid artery and jugular vein. If either is cut, the victim will bleed to death rapidly. Slash-resistant neck guards, balaclavas or high-neck upper-body garments are available to counter this threat.

The area at the side of the neck and around the throat contains the carotid artery and jugular vein. If either is cut, the victim will bleed to death rapidly. Slash-resistant neck guards, balaclavas or high-neck upper-body garments are available to counter this threat.For many years, leather was accepted as providing a good level of protection against cut-related injuries, but it is a heavy and stiff material, and a demand grew for more comfortable protection based on specially engineered fabrics that also allow the wearer a high degree of freedom of movement. Our contribution, for instance is a soft, machine-washable, single-knit fabric (Cut-Tex PRO), which we manufacture on a circular knitting machine at our plant in the UK.

Originally developed for cut-resistant workwear for the flat-glass and sheet-metal processing industries, Cut-Tex PRO fabric has now been field-tested and found acceptance in a wide range of additional applications, such as:

- slash-resistant clothing for security officials;

- bite-resistant clothing for mental healthcare professionals, staff in secure hospitals, special educational needs teachers, and nurses in care homes for the elderly;

- cut-resistant gear for ice-hockey players and ice skaters;

- cut/abrasion-resistant clothing for power boaters.

As flexible as a typical cotton fabric and available in a range of colours, PPSS Group’s Cut-Tex PRO fabric meets international standards for cut-resistance to high levels of performance.

As flexible as a typical cotton fabric and available in a range of colours, PPSS Group’s Cut-Tex PRO fabric meets international standards for cut-resistance to high levels of performance.In addition, the fabric has been tested and certified in accordance with several international standards, including:

- The European Union (EU)’s EN 388:2016 Protective Gloves Against Mechanical Risks, cut-resistance level E (or level 5 as per the earlier 2003 standard);

- The American National Standards Institute (ANSI)/International Safety Equipment Association (ISEA)’s 105 (2016) Standard for Cut Resistance, level A5;

- The International Standards Organization (ISO)’s 13997:1999 Protective Clothing — Mechanical Properties—Determination of Resistance to Cutting by Sharp Objects, level 5.

In fact, Cut-Tex PRO exceeds the maximum ISO cut-resistance (level 5) of 20 N by 149%. For comparison, products made from para-aramid fibres (Kevlar from DuPont of Wilmington, Delaware, USA) are rated at level 3 (5.0 N).

One can imagine, therefore, that cutting such fabric in order to make the garment pieces is a challenge. During the early stages of this project, we tried various fabric-cutting technologies, including circular and straight cutting machines, and water-jet cutters. Ultimately, however, we settled for the first type of cutter we tested, the circular or round cutting machine.

Where on the body is protection needed?

A thorough understanding of human anatomy was important during the research and development (R&D) phase. Cutting of an artery or major blood vessel, for instance, will most likely cause rapid blood loss, subsequent shock and even fatality, so knowing where these are allows us to design clothing properly.

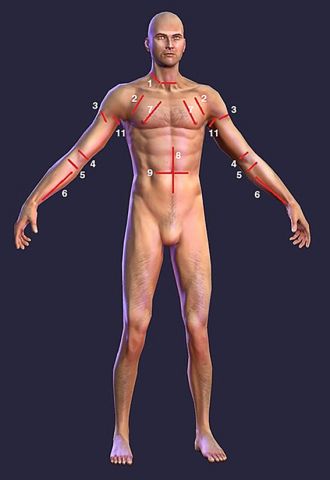

Areas of the body particularly vulnerable to cuts and slashes. By properly understanding human anatomy, suppliers can design effective protection.

Areas of the body particularly vulnerable to cuts and slashes. By properly understanding human anatomy, suppliers can design effective protection.The area at the side of the neck and around the throat (1) contains the carotid artery and jugular vein. If either is cut, the victim will bleed to death rapidly. A horizontal cut across the neck and throat will not only sever the jugular vein and cause death, but it will also cut the trachea and ligaments that control movement of the head. Slash-resistant neck guards, balaclavas or high-neck upper-body garments made from Cut-Tex PRO will make such an injury extremely unlikely.

A deep-enough slash, more than 2.5 cm (one inch), to the inside of the forearm between the radius and ulna bones (6) will sever the radial artery, which can result in unconsciousness in as little as 30 s, and death in as little as two minutes. The radial artery runs across the top of the radius bone, 5–10 cm (2–4 inches) behind the base of the thumb.

The brachial artery runs along the inside of the arms (4–11). It is deep, but severing it will result in unconsciousness in as little as 15 s, and death in as little as 90 s. In addition, injuries in this area cause the muscles of the forearm to contract, pulling on the flexor tendons and potentially depriving victims of the proper use of their hands, so reducing their ability to defend themselves. Slash-resistant arm guards or long-sleeved garments offer substantial levels of protection for these areas.

A powerful cut to the outer side of the pectoral muscle (2) can potentially sever the cephalic vein which will bleed profusely. The same vein is also vulnerable to a cut across the front of the deltoid muscle (3).

A slash across the biceps (4) can disable any motion of the arm and, because the region contains several veins, result in rapid blood loss. Similarly, a slash across the inside of the elbow joint (5) can sever numerous veins and the ligaments that enable motion in the forearm.

Slashing across the pectoral muscle (7) will destroy the victim’s ability to throw punches with any power.

Vertical (8) and horizontal (9) slashes penetrating the abdominal wall will result in loss of motion and potential disembowelment of the victim.

In the thigh is the large femoral artery. Other extremely vulnerable areas are the quadriceps (the muscle group on the front of the thigh) and the region just above the knee, where the muscles in the legs narrow and connect to the patellar tendon. Cuts here can immobilise the victim, an injury known as a “mobility kill”. Slash-resistant long johns have been designed to protect the legs.

Future directions

Using uncomfortable chain mail and heavy leather for protection is clearly a part of history. Lightweight, flexible textiles exist that can take their place. However, the hunt is now on for even thinner, lighter-weight, more durable and more comfortable textiles.

Cut-resistant garments can look like everyday clothing or can be overt pieces of personal protective equipment (PPE).

Cut-resistant garments can look like everyday clothing or can be overt pieces of personal protective equipment (PPE).Protective garments often need to be worn in hot climates, for instance, where temperatures can exceed 40°C and so they need to be extremely breathable. Too many incidents have been reported where professionals failed to wear compulsory PPE because to do so would make them uncomfortably hot.

The challenge is for textile engineers to find the next-generation of cut-resistant materials to continue to save lives.

The following promotional video shows the author Robert Kaiser surviving attacks from a variety of weapons (knives, batons, machetes, baseball bats, shanks and hypodermic needles) while wearing a stab-resistant vest. The video contains scenes some may find disturbing and the attacks it depicts were performed by trained professionals under strictly controlled conditions. Do not attempt to recreate any of these stunts.