Techtera of Lyon, France, is an umbrella organization representing 130 companies based in the Auvergne Rhône-Alpes region of France. The region’s importance to the textile and composite industries is reflected by it accounting for 70% of the French and 18% of European production in terms of tonnage, according to Techtera. A key to the organization’s work is the support it provides for collaborative research and development (R&D). Since 2005, Techtera says it has approved and funded 185 projects, with a combined budget of €510 million. It is currently supporting:

- research into the functionalization of natural fibres by oxyfluoration (ACTINAT);

- the development of polymers with special optical characteristics that can be spun to making multi-filament yarns with photoluminescent and retroreflective properties (EFIGY);

- a project to create high-performance hybrid yarns for protective clothing (NHYCCO);

- the development of geotextile-based systems to protect against natural hazards such as mudslides and rockfalls (PRIDYN);

- research into a bandage embedded with a diagnostic device capable of indicating wound infection (Smart Bandage);

- a material for a balloon-based method of transporting heavy loads (Sealcoat).

At Techtextil, Techtera is supporting 33 of its members who will exhibit, mostly in a combined pavilion in Hall 3.1.

Founded in 1969, Textest AG of Schwerzenbach, Switzerland, has developed a portfolio including:

- a family of air-permeability testers;

- a tester for hydrostatic head;

- test equipment for measuring water vapour transmission rates;

- an apparatus for online measurements of the air-permeability, basis weight and thickness of a moving web;

- an instrument to determine the tear-strength of a textile up to 30 000 cN;

- equipment to measure the thread density of woven and knitted fabrics up to 300 cm–1 (762 an inch);

- an instrument to compare the hardness of bobbins, warp beams and rolls of fabric.

The latest versions of each of these instruments will be demonstrated on the company’s stand.

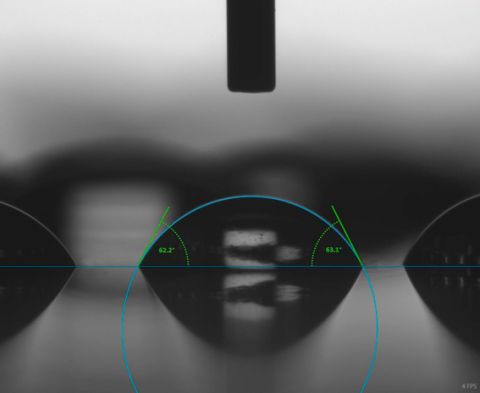

A specialist in interfacial chemistry and measuring instruments for surface and interfacial tension, Krüss GmbH of Hamburg, Germany, will be able to discuss one of its latest developments—software (Advance) for the analysis of drop shapes and the measurement of contact angles. The company will say the algorithm in this program is able to automatically measure even the most difficult images (obscured by extraneous light or shadows, for instance) and interpret even extremely small contact angles (1–10°).

The latest development from Krüss is software (Advance) to help measure small contact angles between surfaces and drops of liquid even where the image is obscured by poor light.

The latest development from Krüss is software (Advance) to help measure small contact angles between surfaces and drops of liquid even where the image is obscured by poor light. Daniel Frese of Krüss spoke at the Nonwovens for High-performance Applications conference about how the company’s technology can be exploited to create better coatings on technical textiles and nonwovens (reference 1)

Daniel Frese of Krüss spoke at the Nonwovens for High-performance Applications conference about how the company’s technology can be exploited to create better coatings on technical textiles and nonwovens (reference 1)The Institut für Textiltechnik(2) (ITA) of RWTH Aachen University, Germany, and its sister organization responsible for technology transfer, ITA Technologietransfer GmbH, are exhibiting from the stand of Krefeld, Germany-based Elmatex. ITA will focus on its research into strong, lightweight materials, including the development of related machinery and processes. Projects include the development of artificial heart-valves and tailgates for vehicles.

The Hohenstein Group(3) of Bönnigheim, Germany, will discuss its broad range of research as well as the services it offers the textile industry (including laboratory testing, certification and labelling of products, consultation and training). However, a key focus of its exhibit in 2017 will be its work on the biodegradation of textiles. On the stand and in a presentation at the Texprocess Symposium, scientists from the Group Hohenstein discuss how they have developed a test procedure for assessing the biodegradation of textiles, as well as demonstrating the marketing opportunities for companies provided by associated certification and product labelling.

To investigate the biodegradation of textiles, researchers at the the Hohenstein Group bury garments, and periodically excavate and inspect them.

To investigate the biodegradation of textiles, researchers at the the Hohenstein Group bury garments, and periodically excavate and inspect them. Other work undertaken by the Group will form the basis of presentations to either the Techtextil Symposium or Texprocess Symposium held during the show:

- Hohenstein will describe its work on the development of a protein-based agent for use as a water-and stain-repellent. The aim is to use biotechnology to produce fungal proteins as a substitute for the polyfluorinated hydrocarbons currently used, which are potentially dangerous to human health and the environment;

- a research project to develop a thermoelectrically cooled bandage for treating patients with acute injuries, at the sites of accidents and after surgery;

- the services offered to help companies manage their use of chemicals responsibly with respect to any impact on the environment;

- the services offered with respect to pattern-making and serial measurements of human forms for fitting garments.